Just-in-Time manufacturing ensures students have accommodation at the start of term.

Brief

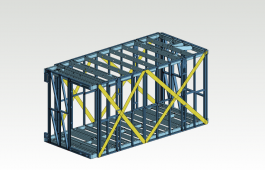

To supply modular steelwork to enable the construction of student accommodation consisting of 54 studio flats, 150 ensuite bedrooms and 2 accessible ensuite bedrooms with associated shared living spaces and kitchens. This high quality 5 storey building is located close to the city centre Newcastle.

The project had to be completed within a rigid time frame, ready for the student intake in September.

Solution

Owing to the immovable completion date a tight factory production programme was adhered to throughout the project, efficiently manufacturing 4 bedrooms per day.

The client benefited from huge time savings during this project. Whilst the demolition and groundworks were taking place, LGSF manufactured the steel modules ensuring no time was wasted in the process.

LGSF worked in partnership with the modular building contractor manufacturing “just-in-time” pre-panelised modules which were supplied to the contractor to be racked, ready for the next shift. This enabled continuous construction to take place offsite. The modules were then landed onsite, at a rate of up to 16 per day, resulting in a rapid onsite build and completion.

Light gauge steel frame modules were produced for the bedrooms, bringing a weight to strength benefit, whilst heavier gauge steel modules provided the strength and space for the larger open plan communal areas.

Results

- Huge time savings thanks to JIT manufacturing and delivery

- Excellent strength to weight ratio

- Safety benefits – light gauge steel framing systems do not contribute to the fire loading of the structure

- Cost efficiencies in transportation gained from supply as a flat pack to the modular client

- Maintenance benefits. Modular steel framework systems have a life expectancy in excess of 60 years